Friday, September 2nd, 2022.

Coming from across the region, a large group of ACB members, met early one warm September morning. With a busy message activity on the Slack channel, finally, we agreed to meet at the information desk at Liverpool Street train station.

The entertainment level was soon on the up as the barrier wasn’t letting one or two of the group through. They’d got the wrong train for their fixed train ticket, and had to find “alternative” methods of getting through the barriers… At least one close encounter with a stranger later, and we all met, ready to move on.

Tube Ride

After an hour’s tube ride across London, we decanted at Turnham Green. Then a 20-minute walk later, and we were looking across the busy A4, Great West Road, at the Mawson Arms sign, and Griffin Hock Brewery window, that makes up part of the historic Fuller’s, Griffin Brewery.

Visitor Centre and Bottle Shop

On arrival at the visitor centre and bottle shop, we noticed that the bar was invitingly open. We soon found the very helpful barman, more than happy to make his recommendation on the range of available cask and keg beers.

A pint or two of London Pride later, and it was time to sign in for our tour.

The Tour

The tour opened with us dropping off our bags in the tour tasting rooms, the Hock Cellar. Then we began the tour in the oldest part of the brewery, where the original mash tun is housed.

Once we were all dressed like a Rail workers Trade Union, dressed in high-vis orange vests, we were separated into two groups and the tour guides gave us the tour. The information was delivered in expert fashion.

The tour included a deep dive on the brewery’s history, beginning with an overview of the original mash tun, copper kettle and square FV. One interesting fact, shared later on the tour, was a small square, is square. And a full size square is a rectangle.

Fuller’s Overview – A Very Brief History

The Griffin Brewery, Chiswick, in West London, opened way back in 1828. It’s since been used to produce Fuller’s Beers for over 170 years. The Griffin Brewery remains as a working brewery, with a huge amount of heritage. The building includes the original, now listed, heritage, steam operated brewery. It is also adorned with the beautiful, and famous Wisteria, which was in full bloom on our visit.

Original Brewery Kit – Steam Power

The original brewery kit, includes a massive cast iron mash tun, copper kettle and a square fermenter. The original brewery was all run on steam power.

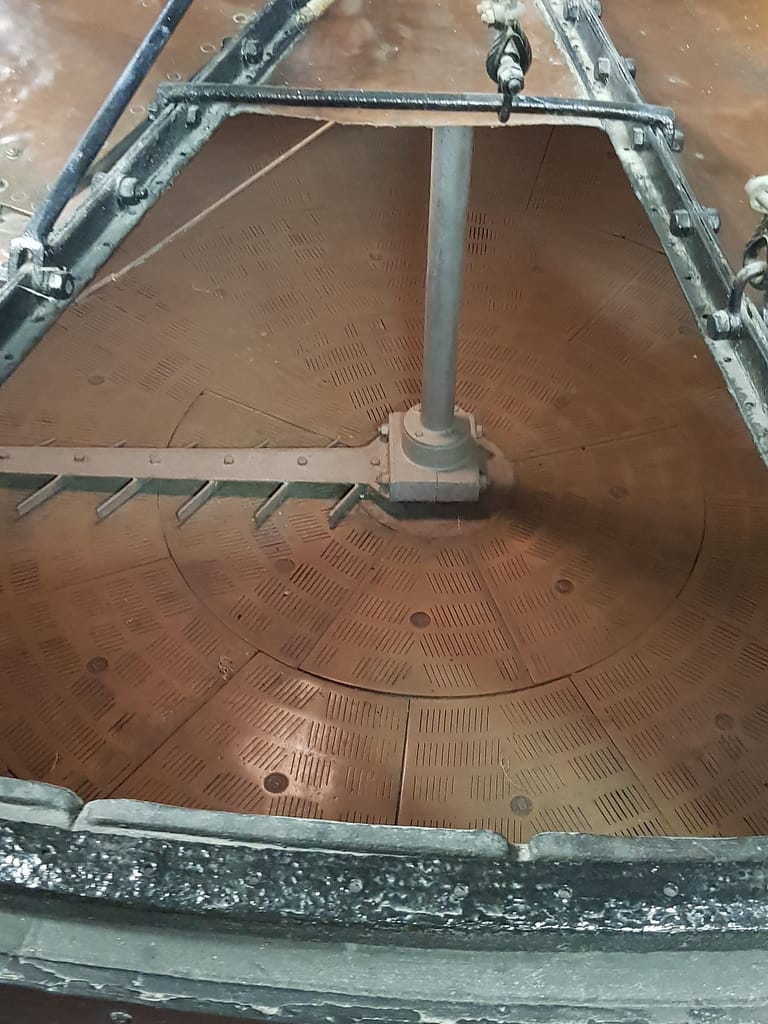

Mash Tun

The mash tun includes the original rake, used to increase mash efficiency, and a huge, slotted false bottom. The false bottom is like a massive industrial jigsaw. It’s numbered, as it only fits in one way. As the cast iron mash tun was installed first, it’s actually on the ground floor.

Copper Kettle and Pumps

The huge, steam heated, copper kettle is the original copper brewing kettle. It’s even older than the mash tun, built in 1823, before Fuller, Smith, and Turner took over. When installed, it was elevated on the first floor. This meant that the wort needed to be pumped into the kettle, from the newer (in modern terms) mash tun, instead of relying on gravity.

The pumps, used to move the massive amounts of water and wort, were also steam powered. The original pulleys and leather belts are all on show, quite the sight.

Square Rectangles – Fermenters

The remaining, original square fermenter was lined with huge sheets of copper. It included the original sluice gate. The gate was used to harvest the actively fermenting Krausen, which was used to ferment the next batch of beer.

The “square” also included the original square tubes of copper pipe, used to cold-crash the beer. Our tour guide, John, hinted that the beers would have originally been crashed using cold water, and later, the brewery would have used glycol.

The Modern Brewery

The newer, modern side of the brewery, is, as you’d expect, very shiny and contains entirely stainless steel vessels. Our tour was held on a Friday, which is cleaning day. This meant that the brewers were busy monitoring various control panels as they carried out CIP routines and maintenance procedures.

Head Brewer

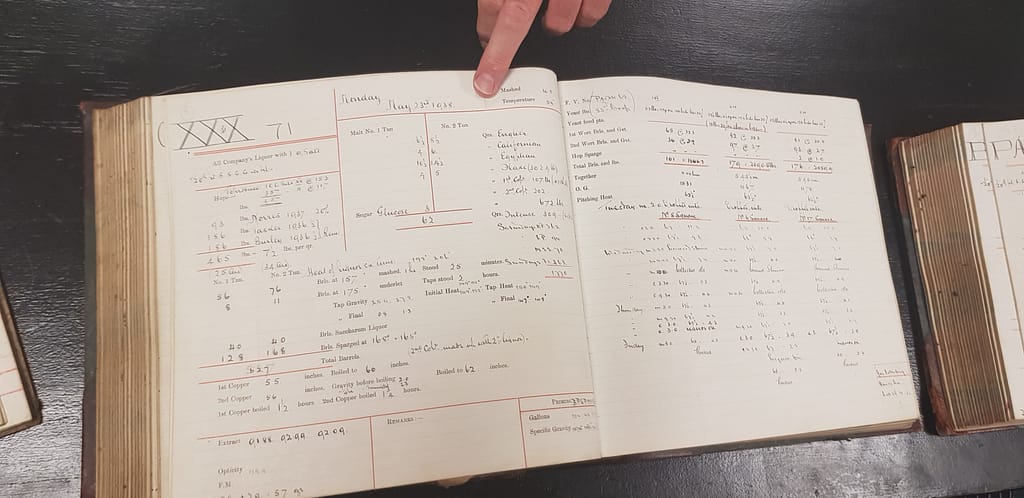

During the overview of the massive stainless mash tuns, Guy Stewart, Fuller’s head brewer, popped his head out. He showed up to kindly invite us into a meeting room. Inside the room, he’d laid out a selection of huge, historic recipe books and tax returns from the 1900’s.

Automated Keg Washing and Filling Line

The last leg of the tour included a look through the keg and cask lines. Inside we witnessed the younger relation of ED209, from Robo Cop, who’s no longer needed to keep control of unruly brewer’s. Instead, now it’s used for the repetitive task of de-palleting kegs, 3 at a time, and placing them on the automated conveyor belt that feeds the automated keg washer and filler.

Fuller’s still fill casks by hand, favoring the more manual approach for what they still see as their premium, live product.

The Hock Cellar

After the tour, everyone decanted, back to the Hock Cellar to sample the full range of Fuller’s beers on cask, keg and bottles.

London Pride Taste Test with Fuller’s Head Brewer – Guy Stewart

Part of the tour was to have Fuller’s head brewer, Guy Stewart, judge our brewer’s range of London Pride clone beers. In early August, we’d chosen the best of the selection of LP clone beers to take forward, for Guy to judge. Guy is best placed to judge the clones, as the head brewer, and being in charge of the panel of tasters on Fuller’s quality control process. It’s fair to say, Guy can be regarded as an expert on the nuances of London Pride.

After tasting all four beers, Guy selected Keith Bailey’s representation of London Pride as his winner. Guy stated that he thoroughly enjoyed the beers and thought Keith’s beer was a great representation of London Pride.

Well done to Keith, who took the kudos well, edging John Watson into second place. Keith was kindly presented with a selection of Fuller’s bottles by Guy.

Round up

All in all, the tour was a resounding success and well worth the effort.

Afterwards, we took a 20-minute stroll along the River Thames, taking in a recommendation to visit a Fuller’s pub on the river, The Dove. This pub is well worth a visit.

Once assembled, many of the group enjoyed some lovely food inside. Later, it moved back to pints, where we found our way outside, to the amazing split-level mezzanine, that overlooks the river.

The view to a busy Hammersmith Bridge, was delightful in the warm, early autumnal evening air. The beer and the conversation flowed, as we soaked in the atmosphere.

Thank You

I’d like to extend thanks to Nik Leng, for organising the tour, tasting, and liaising with the Fuller’s team.

A special mention goes out to the Fuller’s tour team, who were excellent on the day, and went out of their way to get answers to our various questions.

Finally, massive thanks to Fuller’s head brewer, Guy Stewart. Guy was brilliant to us on the day. He’s a really genuine, nice guy. As you’d expect, a hive of technical information and tips on the brewing process. He was only too happy to share his knowledge with us regarding more Fuller’s clone beers, that we wanted to brew, back at home.

Bonus Information

The Hock Cellar tasting was rounded off with a special tasting, with Guy covering an overview of the 1845 recipe. The tour closed with the promise of the 1845 recipe to follow (see below).

Fuller’s Recipes

Fuller’s 1845 Recipe

Grist:

- 75% PA malt

- 20% Amber

- 4% Crystal light

- 1% Chocolate – this is to hit the colour spec

Hops:

- 52 IBU’s of Goldings for both bitter and aroma

Vital Statistics:

- OG – 64.5

- Alc – 6.3

- Col – 57

- BU – 52

Fuller’s Black Cab Recipe

Grist:

- 60% PA malt

- 14% Crystal light

- 11% chocolate

- 8% Munich

- 7% Golden naked oats

Hops

- 40 IBUs of Goldings for bittering and aroma

Vital Statistics:

- OG – 46

- Alc 4.5

- Col – 160

- BU 40